For an OEM, work does not stop after selling a machine or vehicle. The real test starts when your dealer teams have to keep customers happy after the first sale. This is why the aftermarket is important. If parts are not there on time or service is slow, customers lose trust. Many OEM aftermarket operations challenges happen because systems are slow, stock is wrong, or service is not tracked properly.

When OEM parts management is done on paper or old software, mistakes happen easily. Dealers may wait for parts that are needed fast, while parts that are not needed much sit in the store. Without proper OEM inventory management, you spend more money and lose sales. Warranty work can also slow your business if you do not have good OEM warranty management software. This makes dealer teams stressed and customers unhappy.

The truth is, problems in OEM inventory and other aftermarket issues do not go away by themselves. But smart tools and simple ways of working can make life easier for your dealer network and keep customers happy. This article talks about the main problems OEMs face in the aftermarket and simple, smart ways to solve them.

Why the Aftermarket is Important for OEMs

The aftermarket is not just about selling spare parts or fixing machines. It is also about keeping dealer teams and customers happy after the first sale. When dealers get the parts they need fast, fix problems, or handle warranty claims quickly, it builds trust. Happy dealers mean happy customers, and that keeps your business growing.

Manufacturing has changed a lot in recent years. Since the 1990s, new technology, global competition, and big events like COVID-19 have made it tougher for OEMs. Supply chains got broken, and many businesses found it hard to keep up. Today, challenges in OEM inventory and other aftermarket problems can hurt your profits and reputation if you do not act.

The good news is you do not have to struggle alone. With the right tools and simple ways to work, you can make your operations smoother. Let us look at the biggest problems and how to solve them.

The Biggest Aftermarket Challenges Faced by OEMs

1. Running Out of High-Demand Parts

Imagine a dealer getting a call from a customer who needs a part fast, only to find it is not in stock. This is one of the biggest problems in OEM parts management and OEM inventory management. If you do not have the parts your dealers need, it delays work, makes customers unhappy, and you lose sales.

Why does this happen? Many OEMs still use old ways to track stock, like spreadsheets or paper records. They cannot tell which parts will be needed most, so you may have too many of one part and not enough of another. Without real-time data or smart forecasts, challenges in OEM inventory keep happening.

What Happens Because of This?

Dealers cannot give parts on time, which makes customers unhappy.

Dealers may lose sales to shops that have parts ready.

You spend more money on rush orders to fix shortages.

2. Struggling Without Automation

Managing aftermarket work is like juggling many things at once. You have to handle stock, take orders, talk to dealers, and sort warranty claims. Doing this manually is slow, tiring, and full of mistakes. Many OEMs face a choice: buy ready software or make their own. Custom software is costly and slow, but wrong software can cause more problems.

Without automation, OEM aftermarket operations’ challenges like slow orders or mixed-up stock get worse. Your team wastes hours on repeating work, and dealers get frustrated waiting for updates.

What Happens Because of This?

Your team wastes time checking stock or filling forms.

Mistakes in orders or stock upset dealers.

You spend more money because things are slow.

3. Messy Warranty Management

Warranty claims are important, but they can be tricky. Some claims may be fake, costing money. Others may show parts that are not as good as they should be. If the warranty process is slow or confusing, it annoys dealers.

Without good OEM warranty management software, claims are like a puzzle with missing pieces. Dealer teams struggle to submit claims, and staff waste time chasing approvals.

What happens because of this?

Fake claims eat into profits.

Slow process makes dealers unhappy.

The team wastes time on paperwork instead of fixing products.

4. Communication Gaps with Dealers

Dealers are your partners, but poor communication can cause problems. Many OEMs do not have a central system to share updates. Dealers may not know about new parts, deals, or how to report problems. This slows work and makes dealers unhappy.

What Happens Because of This?

Dealers wait too long for parts or help.

You miss chances to sell more.

Relationship with dealers gets weaker.

5. Complicated Returns Process

Returns can be tricky. Dealers expect it to be fast. But slow shipping, wrong labels, or human mistakes make returns a hassle. Without a smart system, managing returns costs time and money.

What Happens Because of This?

Dealers get frustrated with slow returns.

You lose money due to shipping mistakes.

Team wastes hours fixing return problems.

6. Old Manuals and Documents

Dealers need manuals to fix machines or explain parts. Old PDF manuals are long, hard to read, and hard to search. Dealers cannot find info fast, which slows work and annoys customers. Updating PDFs is also a headache.

What Happens Because of This?

Dealers waste time searching in big PDFs.

Customers get frustrated.

You spend extra time and money updating files.

7. Slow Technical Support

When dealers have technical problems, they need help fast. Without a proper system, issues take days or weeks to solve. Slow support makes dealers unhappy and customers lose trust.

What Happens Because of This?

Dealers wait too long for fixes.

Customers get upset.

The team wastes time instead of solving problems.

How OEMs Can Manage Aftermarket Challenges

The key is using smart, simple tools that make work easier and help dealer teams shine. These solutions tackle OEM aftermarket operations challenges.

1. Smart Spare Parts Management

A good spare parts system is like giving dealers a smart e-catalog. They can find and order parts in just a few clicks. Real-time stock updates prevent shortages.

How it helps:

Dealers find parts fast.

Inventory shows low-stock items early.

Dealers are happy and trust you more.

2. Streamlined Warranty Management

A simple warranty module makes claims easy. It tracks claims from start to finish.

How it helps:

Reduces losses with approvals.

Dealers get answers quickly.

Less paperwork saves money.

3. Advanced Technical Helpdesk

A helpdesk system lets dealers report problems and get solutions fast. Tickets and a knowledge base make work easier.

How it helps:

Urgent issues go to the right team fast.

Dealers and staff communicate easily.

Solutions are saved for future use.

4. Predictive Maintenance Support

AI-driven system can flag service needs of a vehicle before that vehicle breaks down. This reduces downtime and improves satisfaction.

How it helps:

Alerts for service needs early.

Cuts downtime and improves reliability.

Customers are happy with timely service.

5. E-Catalogue & Service Bulletin

Keep dealers updated with one place for parts and manuals. Cloud-based access lets them use it anywhere.

How it helps:

All parts and updates in one catalog.

Search better with help of drawings highlighting parts in every vehicle variant.

Real-time updates keep all dealers aligned.

Note : The e-catalog and AI-Based features are available as add-on with NetFlows360. It lets OEMs make their main dealer system bigger and better with a smart digital catalog and service bulletin hub.

6. Sales & Purchase Return Management

A structured system makes returns easy. Dealers send back parts, and OEMs process them fast.

How it helps:

Dealers track return requests easily.

OEM has visibility of sales/ purchase returns.

Credits or replacements are faster, building trust.

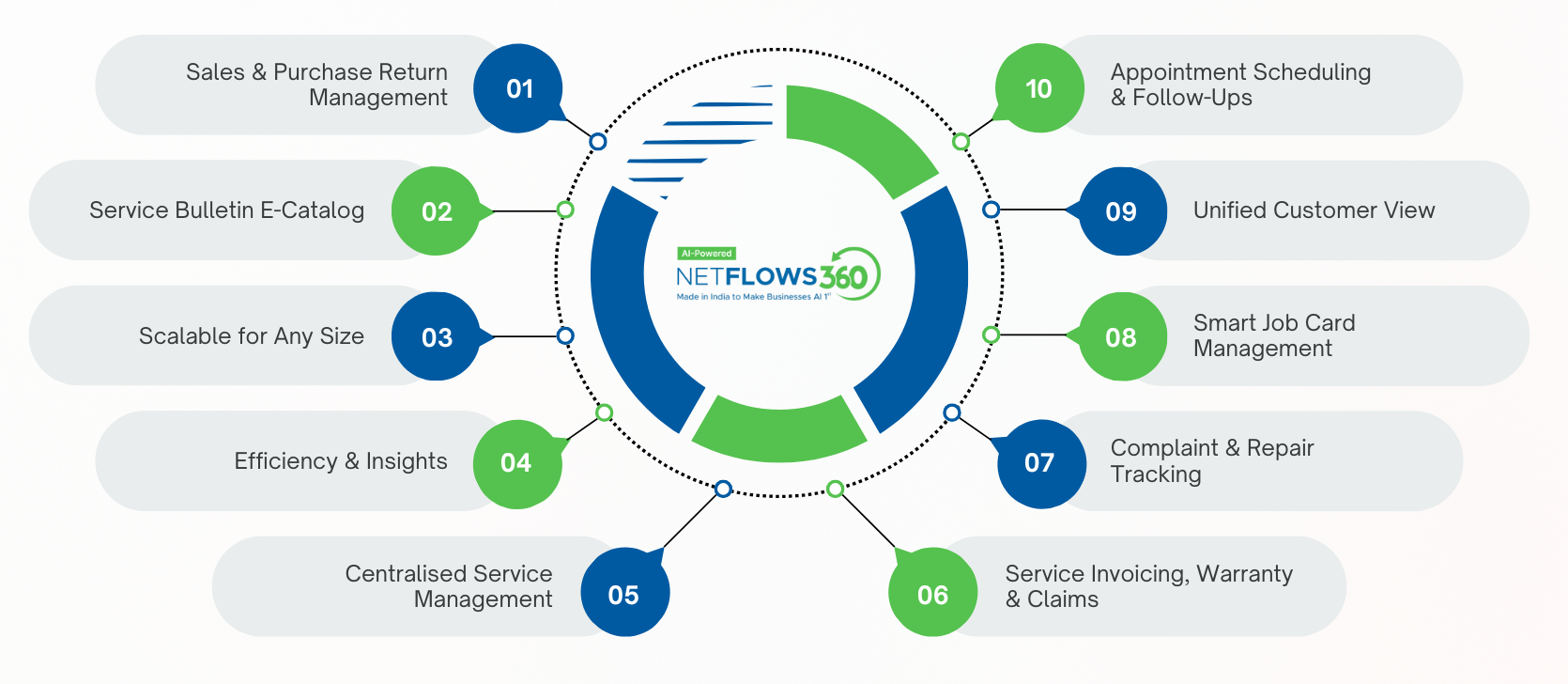

How NetFlows360 Helps OEMs

NetFlows360 is an AI-Powered DMS that solves aftermarket problems. It keeps operations fast, visible, and connected.

Sales & Purchase Return Management – Track all return requests with full visibility.

Unified Customer View – Track sales, service and claims done by dealer network.

E-Catalog – Latest variant designs, updates, and parts in one place. This feature is an add-on with NetFlows360. It lets OEMs make their main dealer system bigger and better with a smart digital catalog and service bulletin hub.

Scalable for Any Size – Works for startups to big OEMs.

Efficiency & Insights – Real-time reports track team performance.

Centralised Service Management – Bookings, job cards, invoices, warranty claims in one place.

Appointment Scheduling & Follow-Ups – Organized dealer workshops and send reminders.

Complaint & Repair Tracking – Track repairs and complaints.

Service Invoicing, Warranty & Claims – Track claims in real-time for smooth dealer sync.

With NetFlows360, nothing falls through cracks. Dealers work faster, customers get quick fixes, and aftermarket operations stay under control.

See how NetFlows360 increased speed by 60% for a top commercial vehicle maker.

Explore the Full Story

Wrapping Up

OEM aftermarket operations challenges are not just about systems—they are about people. Dealer teams, dealer network, and customers all rely on you.

Smooth inventory management avoids stockouts, speeds up service, and earns trust. A good warranty module makes claims fast and fair, freeing your team to focus on happy customers.

Yes, inventory challenges will always exist. Demand changes, suppliers may delay, and unexpected situations test your plans. But with the right tools like NetFlows360, real-time data, and a focus on your dealer network, you can turn problems into opportunities.

Want to beat these aftermarket challenges faster? Book a free demo and see how NetFlows360 can make your work easy.

Frequently Asked Questions (FAQs)

OEMs face running out of spare parts, slow manual work, messy warranty claims, poor dealer communication, and tricky returns. These delays work and make customers unhappy.

OEMs use smart software to automate tasks like parts management, warranty claims, and technical help. This saves time, reduces mistakes, and helps dealers work faster.

The best software has digital catalogs, search tools, and real-time stock updates. Dealers find and order parts quickly and avoid shortages.

Software with easy catalogs, real-time updates, and fast ordering is best. Dealers get parts fast, and stock stays under control.

It makes claims easy, from submission to approval. Dealers get faster answers, losses are reduced, and paperwork is less.