The automotive manufacturing ecosystem is undergoing its biggest transformation in decades. What once relied on physical showrooms, manual coordination, and siloed dealership tools now demands real-time intelligence, connected workflows, and unified visibility across the entire value chain. As customer journeys expand across digital and physical touchpoints — and as OEMs push for greater efficiency, profitability, and control — the role of the Dealer Management System has evolved from a basic operational tool into a strategic growth engine.

The DMS Shift in Automotive Manufacturing

Dealer Management Systems started as “dealer ERPs” – a way to run day-to-day operations like pre-sales, sales, service, inventory, and accounting from one place. They connect OEMs, distributors, dealers, and customers across the network.

But the automotive manufacturing space has changed:

- More touchpoints, more channels

Buyers move between websites, social media, call centers, showrooms, and service bays. One disconnected system can’t keep up with this journey anymore.

- Tighter competition and thinner margins

OEMs need to see real profitability by dealer, by model, and by region—not just raw units sold.

- Faster technology cycles

Cloud, APIs, IoT, connected cars, and AI are now standard expectations, not “future ideas.”

Why Traditional Automotive DMS Setups Fall Short

Legacy dealer management system software was built for a very different world. Today, it often holds OEMs back more than it helps.

- Hard to scale across networks

Many OEMs run old, on-premises DMS instances with thick clients and custom code. Adding new dealers, new markets, or new brands quickly becomes complex and expensive.

- Costly to change or upgrade

Every small change—new scheme, new process, new tax rule—needs heavy development, hardware upgrades, or new licenses. This slows down innovation and increases total cost of ownership.

- Limited access and poor performance

During festive seasons, month-end, or high-traffic campaigns, on-premise systems accessed over WAN often lag or crash, frustrating dealers and sales teams.

- Weak visibility across the chain

Traditional automotive DMS setups focus on the dealership level. OEMs still can’t easily see real-time performance across all dealers, all regions, or the full vehicle lifecycle.

- Minimal intelligence, mostly transactional

Older systems process orders and invoices but do little to forecast demand, spot at-risk customers, or optimize inventory.

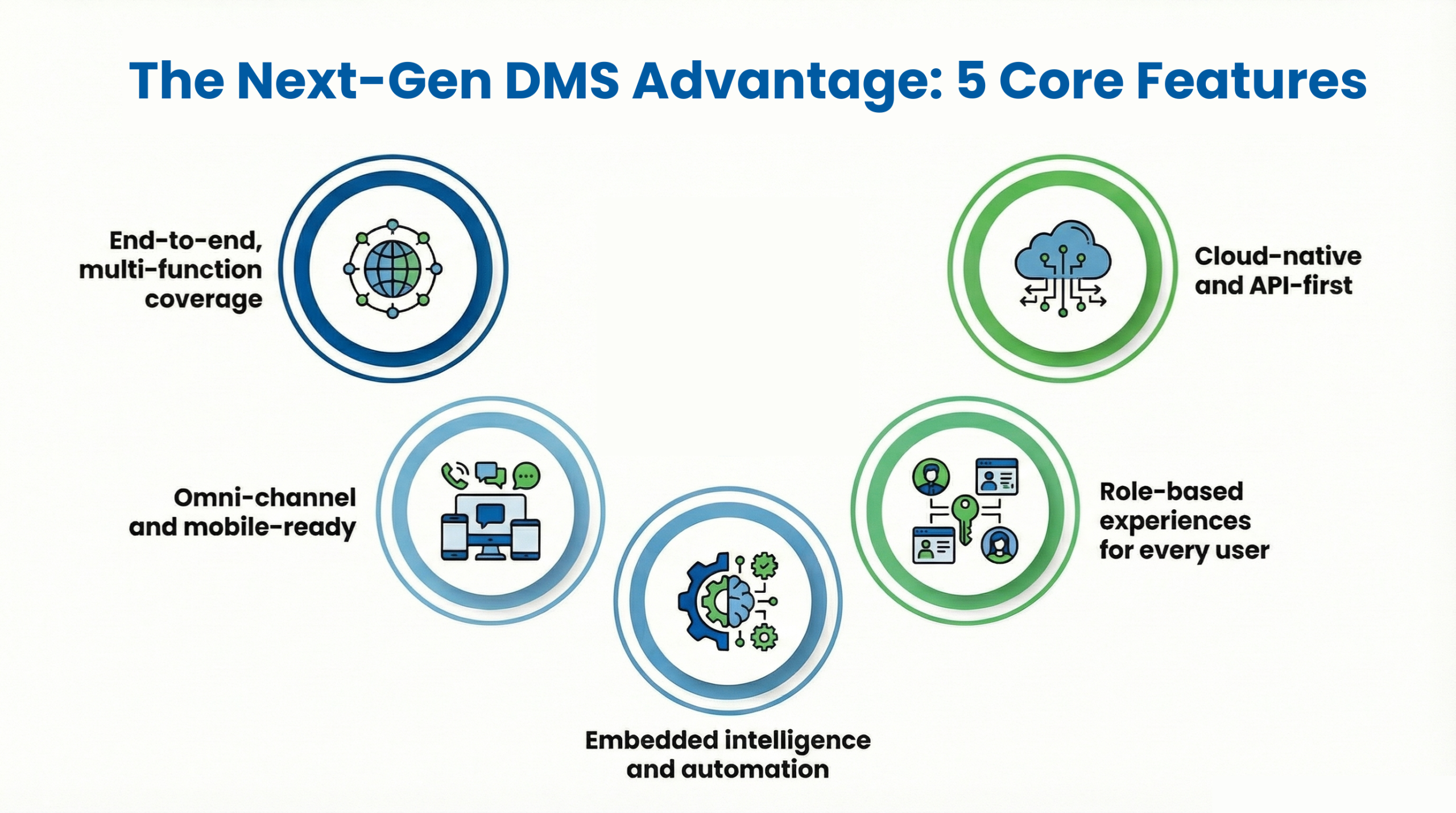

What Makes a Next-Gen Dealer Management System Different

A next-gen dealer management system is not just a software upgrade—it’s a new way of running the OEM–dealer network.

- End-to-end, multi-function coverage

Modern dealer management system software supports pre-sales, sales, service/aftersales, inventory, finance, CRM, and HR from a single backbone, so every process uses the same trusted data.

- Cloud-native and API-first

Next-gen systems are built with microservices and open APIs, making it simpler to connect with ERP, CRM, finance systems, e-commerce, telematics, IoT devices, and third-party apps.

- Omni-channel and mobile-ready

Sales and service teams can work from desktops, tablets, or mobile devices with “anytime, anywhere” access—even in low-connectivity locations—while data keeps syncing in the background.

- Role-based experiences for every user

Dealer principals, sales advisors, service writers, parts managers, and OEM teams see dashboards tailored to their responsibilities instead of generic screens for everyone.

- Embedded intelligence and automation

Built-in analytics, alerts, and workflows help teams act quickly—whether it’s a stockout warning, a low lead-to-sale conversion, or delayed job cards.

Core Capabilities of a Next-Gen Automotive DMS

A future-ready DMS is designed to unify every part of the OEM–dealer ecosystem. Instead of operating in silos, all functions—sales, service, parts, inventory, finance, CRM, and network reporting—run through one intelligent platform. This creates a consistent experience for dealers and gives OEMs complete visibility into how their network performs day to day. A modern DMS replaces scattered tools and manual processes with a connected system that manages bookings, test drives, orders, repairs, parts movement, customer interactions, and financial workflows from a single backbone. With real-time data syncing across outlets, both OEMs and dealers gain a clear picture of business health without relying on fragmented spreadsheets or legacy systems.

AI and automation elevate these capabilities even further. The system continuously learns from booking trends, service workloads, technician productivity, parts usage, and regional demand patterns. This helps teams prioritize leads, reduce service bottlenecks, improve forecasting, and eliminate repetitive manual tasks. With consistent data flowing across every function, OEMs can make network-wide decisions swiftly and accurately.

A next-gen DMS also acts as a real-time decision engine for the entire OEM–dealer network. It consolidates data from sales, service, parts, inventory, and finance to deliver a single, trustworthy view of performance across regions and outlets. Leaders can understand how each dealership is performing, spot early signs of demand or service issues, and adjust targets or allocations instantly. From booking trends to technician output to contribution margins by model, everything becomes visible through unified dashboards, enabling OEM teams to identify underperformance early and scale best practices network-wide.

With embedded analytics, the system forecasts what may happen next—models that might slow down, parts at risk of shortage, service centers likely to experience load spikes, or outlets in danger of missing targets. Instead of reacting late, OEMs can take timely actions to protect revenue, reduce ageing, and strengthen customer experience. Role-based insights further enhance this clarity: OEM executives gain enterprise-level views for strategic planning, while dealers receive operational dashboards to manage day-to-day activities like RO closures, bay utilization, lead follow-ups, and sales pipeline accuracy. Together, this ensures every stakeholder—from the factory to the showroom—operates with alignment, intelligence, and confidence.

Experience Matters: How Next-Gen DMS Improves OEM–Dealer Collaboration

A next-gen dealer management system is not only a technology upgrade—it reshapes how OEMs and dealers work together. In a modern automotive manufacturing environment, the strength of the OEM–dealer relationship determines how fast decisions are made, how accurately demand is planned, and how consistently customer promises are delivered across the network.

- Alignment Across OEM and Dealer Workflows

Next-gen DMS platforms unify processes across sales, service, inventory, and aftersales. Instead of each dealer running isolated systems, OEMs gain a synchronized view of activities happening across every outlet. This reduces gaps in communication, removes duplication of effort, and ensures that network-wide strategies translate into consistent on-ground execution.

- Faster Response to Market and Model-Level Signals

Dealers are often the first to sense shifts in demand. A modern DMS captures these signals—test drives, inquiries, cancellations, footfall trends—in real time, allowing OEMs to adjust production plans, regional allocations, and marketing campaigns much faster. This closes the feedback loop between the showroom floor and the factory floor.

- Improved Technician and Service Efficiency Through Centralized Data

A next-gen DMS gives technicians and service teams access to model-wise repair histories, part availability, and service bulletins from a single platform. This reduces guesswork, shortens repair cycles, and ensures that aftersales teams follow consistent diagnostic and repair standards across all dealers.

- Predictable and Transparent Network Performance

OEMs require clear visibility into dealer-level KPIs such as bookings, turnaround times, RO closures, parts consumption, and conversion ratios. A next-gen DMS standardizes how these metrics are tracked and reported, giving OEM leaders a dependable foundation for forecasting, target-setting, and performance interventions.

- Scalable Operations with Lower Training and Transition Costs

Modern DMS platforms simplify onboarding for dealer principals, sales staff, parts managers, and service advisors. With role-based screens, guided workflows, and consistent logic across modules, new team members adapt quickly, reducing training costs and ensuring uninterrupted operations—even during staff turnover.

Why OEMs Choose NetFlows360 for Their Next-Generation DMS Evolution

Transitioning to a next-generation DMS is not just a software shift—it is a complete transformation in how OEMs and dealers collaborate, manage customers, and run end-to-end operations. NetFlows360 is built to support this evolution, enabling OEMs to modernize workflows, unify data, and bring intelligence into every part of the dealer network.

NetFlows360 helps OEMs evaluate their current digital maturity by revealing where processes are fragmented, where manual work still slows teams down, and where critical decisions rely on outdated systems. With this clarity, OEMs can focus on the areas that need immediate modernization—whether it’s inventory intelligence, aftersales efficiency, reporting accuracy, or elevating customer experience across outlets.

The platform is designed around a unified data and integration framework, allowing ERP systems, CRMs, connected vehicle systems, finance tools, and dealer apps to operate in a shared data environment. This ensures real-time insights, accurate forecasting, and consistent dashboards, giving OEMs a complete and trustworthy view of their network.

NetFlows360 also strengthens adoption across teams. Sales advisors, service writers, parts managers, and OEM field executives gain intuitive, role-based tools that make their daily tasks faster, simpler, and more intelligent. When teams understand how the platform improves their own productivity, usage rises naturally—and the impact multiplies across the network.

Ultimately, NetFlows360 delivers its full value when OEMs embrace this connected, future-ready way of working. It’s not just a DMS—it’s the foundation for a smarter, more synchronized, and insight-driven OEM–dealer ecosystem.

Wrap Up

For automotive manufacturers, the DMS is no longer just another back-office tool—it’s the digital backbone of the OEM–dealer network.

A next-gen dealer management system brings together:

- Robust inventory management software solutions

- Smart dealership reporting software and analytics

- Integrated, cloud-native OEM solutions

- A flexible, secure automotive DMS architecture that can evolve with your strategy

OEMs that modernize their DMS now will be better positioned to control inventory, strengthen dealer performance, and deliver superior customer experiences in a market that’s only getting more competitive.

FAQs

A next-gen dealer management system is an advanced automotive DMS that goes beyond basic billing and order management. It connects sales, service, parts, inventory, finance, and CRM across OEMs and dealers, with built-in analytics, mobile access, and cloud-ready architecture.

Legacy systems are usually on-premises, hard to integrate, and focused on transactions. Modern dealer management system software is cloud-based, API-driven, mobile-first, and designed to support end-to-end processes and real-time decision-making for both OEMs and dealers.

Inventory drives both revenue and cost. Integrated inventory management software solutions inside the DMS help OEMs and dealers see stock in real time, align production with demand, reduce ageing inventory, and ensure the right parts and models are available where they’re needed most.

OEMs should look for dealership reporting software that consolidates data across all dealers, offers real-time dashboards, supports drill-down by region/dealer/model, and includes predictive analytics to flag risks and opportunities early.

Modern OEM solutions use the DMS as a central hub. The DMS collects transactional and operational data, while OEM systems handle planning, product strategy, and corporate analytics. Through APIs and shared data models, they work together to deliver one consistent view of the network.