If you’re an OEM selling vehicles or farm equipment, selling the product is just the start. The real challenge? Making sure your customers get help after buying. And the most important part of that help is having spare parts ready when they need them.

Your dealer teams are the first people customers go to. If a part isn’t there, repairs take longer, customers get annoyed, and your dealers feel stressed. Over time, this can hurt how much people trust your brand. That’s why proper parts management is super important for every OEM.

A smart spare parts inventory management system makes sure dealer teams always have what they need. With vehicle tech changing fast and customer demand being hard to guess, OEMs need smarter ways to do spare parts planning.

This article will show why good spare parts planning matters, how your dealer networks benefit, and how AI is changing the way parts are managed.

What Is Spare Parts Management?

Think of spare parts management like a big toolbox for your dealers. It’s about making sure the right parts for EVs, two-wheelers, tractors, or other vehicles are ready when your dealer network needs them. It’s not just storing parts or counting stock—it’s knowing what’s there, what’s needed, and how to get it fast.

Picture this: your dealer team needs a battery for an EV, a clutch for a tractor, or a brake pad for a two-wheeler. Good parts management makes it easy to find. A strong spare parts inventory management system shows your dealer network what’s available so they can fix things fast and make customers happy.

Key Steps in Parts Management

Here’s how OEMs can do spare parts planning the right way:

1. Forecasting Needs : Use data about how vehicles are used and which parts break the most. For example, EV batteries or tractor blades may wear out faster depending on use. Predicting this helps your dealers stay ready.

2. Tracking Inventory : Keep track of all parts in warehouses and stores. Think like a shopkeeper checking stock. A good parts inventory management system makes this simple.

3. Ordering Parts : Work with suppliers to restock parts before they run out. No one likes to wait for a part.

4. Distributing Parts : Make sure parts get to dealers fast so repairs happen quickly.

These steps make parts management easy, keep vehicles moving, and keep customers happy.

Why Spare Parts Inventory Is Important

A strong parts inventory management system is the backbone of OEM work. Here’s why:

1. Keeping Vehicles Running

If a vehicle breaks down—like a two-wheeler, EV, or tractor—dealers need tyres, batteries, or belts fast. A good parts inventory management system makes repairs quick, so customers aren’t stuck.

2. Saving Time and Money

Idle vehicles cost money. A farmer with a broken tractor loses workdays. A delivery driver with a faulty EV misses deliveries. Rush orders are pricey. Good spare parts management stops stockouts, saves money, and keeps your dealer network running.

3. Making Customers Happy

People want quick service. When dealer teams have parts, repairs are fast. An EV owner loves a quick battery swap, and a farmer wants a fast tractor repair. Happy customers trust your brand.

4. Avoiding Waste

Too many parts waste money; too few cause delays. A smart spare parts inventory management system keeps just enough parts so there’s no waste.

5. Strengthening Your Dealer Network

Dealers need systems that work. Tools like NetFlows360 give them real-time info so they can serve customers better. Good spare parts planning for OEMs keeps the network strong.

Drawbacks of Poor Spare Parts Management

Poor parts planning causes lots of problems:

Vehicles Stay Idle : No parts, no repairs. Two-wheeler shops without batteries or tractor dealers without clutches can’t help customers. That frustrates people and hurts your reputation.

Higher Costs : Delays mean rush orders that cost more. Out-of-stock parts force dealers to spend extra on fast shipping.

Unhappy Customers : Slow repairs upset people. A farmer waiting days for a tractor part might switch brands. In India’s competitive market, bad word spreads fast.

Lost Business : Down vehicles mean lost money. Delivery drivers miss orders. Farmers can’t plant crops. If dealers can’t get parts quickly, customers may go to competitors.

Supply Chain Chaos : Bad parts management messes up the whole supply chain. Missing parts slow everything down.

Tired of delays, stockouts, and angry customers? Smarter spare parts management is the way to zero downtime.

5 Tips to Improve Spare Parts Management

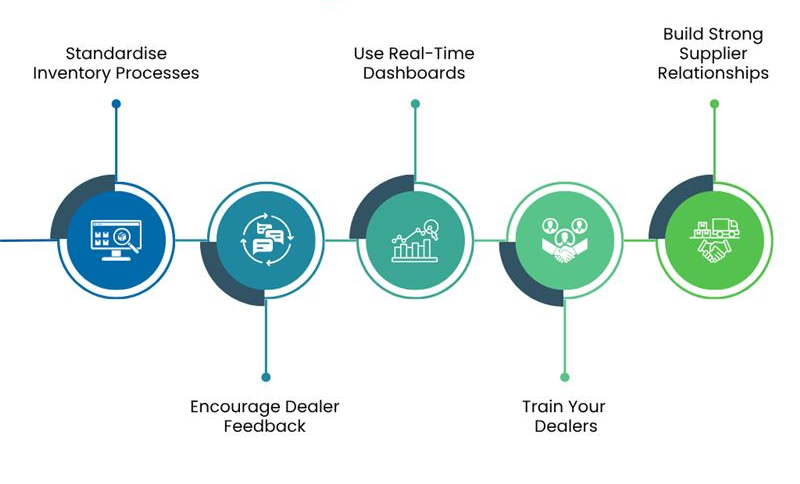

Here are five ways to boost parts planning and help your dealers:

1. Standardise Inventory Processes

Set clear rules for tracking and managing parts across dealers. For example, how often to check stock and reorder EV batteries or brakes.

Why it helps: Standardisation reduces mistakes and makes parts management smooth.

2. Train Your Dealers

Teach them to spot problems and use the inventory system like NetFlows360. Training is like coaching a sports team—it makes them faster and better. Why it helps: Well-trained dealers fix things quickly and get parts to customers fast.

3. Build Strong Supplier Relationships

Reliable suppliers make sure critical parts arrive on time. Tools like NetFlows360 help track availability across dealers. Why it helps: Strong supplier links make your parts inventory management system dependable.

4. Use Real-Time Dashboards

Dashboards show stock, order status, and part locations. Dealers can act fast without guessing. Why it helps: Real-time info stops delays and keeps vehicles running.

5. Encourage Dealer Feedback

Listen to dealers about shortages or problems. If some parts, like tyres, are always low, adjust stock. Why it helps: Feedback fine-tunes your OEM spare parts strategy so inventory meets real needs.

Why it helps: Feedback fine-tunes your OEM spare parts strategy so inventory meets real needs.

How NetFlows360 Makes Spare Parts Management Easy

Delays frustrate customers and hurt your brand. A system like NetFlows360 ensures dealers always have the parts they need.

Real-Time Stock Updates: Dealers know exactly what’s in stock.

Automatic Reordering: NetFlows360 identifies low stock level and creates draft order requests within dealer portal, so that dealer teams just need to validate and place order.

Faster Returns and Transfers: Whether a customer returns a part or a dealership transfers it, NetFlows360 tracks every move, keeping the ecosystem in sync.

Less Waste, Better Planning: The system can analyze and show parts moving faster and the ones sitting unused, helping your dealer network avoid overstocking and improve your OEM spare parts strategy.

Clear Billing and Reports: Every part used, sold, or transferred is tracked in real time, giving OEM and dealer teams clear data to make smart decisions.

Control Across Locations: From ordering to invoicing, everything is tracked.

NetFlows360 lets dealers focus on fast service instead of worrying about missing parts.

Wrapping Up

For OEMs making EVs, two-wheelers, three-wheelers, four-wheelers, or farm equipment, parts management is key.

Using NetFlows360, doing smart parts planning, training dealers, and building supplier relationships ensures parts are ready. Vehicles stay on the road, costs stay low, and customers stay happy.

A good OEM spare parts strategy reduces downtime, builds trust, and keeps your dealer network strong. Start optimising spare parts management today to keep your customers smiling and business thriving!

Want to control your spare parts operations? Book a Free Demo of NetFlows360 and see it work across all your dealers.

Frequently Asked Questions(FAQs)

Use AI, real-time data, and software like NetFlows360 to guess which parts are needed, track stock across dealers, and avoid shortages or overstocking. Good parts management makes operations smoother./p>

It tracks parts everywhere, automates reordering, and shows what’s in stock. This strengthens your OEM spare parts strategy so dealers can serve customers quickly.

It causes delays, stresses dealers, and hurts customer trust. Idle vehicles, rush orders, and lost sales happen without proper parts planning.

Yes! It’s built for OEMs to manage inventory everywhere with one dashboard and full control.

It’s built for Indian OEMs, offering real-time visibility, automated processes, and data-driven insights. It replaces spreadsheets and guesswork, helping your dealer teams make smarter decisions.